MyEDC account

Manage your finance and insurance services. Get access to export tools and expert insights.

Solutions

By product

By product

By product

By product

Insurance

Get short-term coverage for occasional exports

Maintain ongoing coverage for active exporters

Learn how credit insurance safeguards your business and opens doors to new markets.

See how portfolio credit insurance helped this Canadian innovator expand.

Guarantees

Increase borrowing power for exports

Free up cash tied to contracts

Protect profits from exchange risk

Unlock more working capital

Find out how access to working capital fueled their expansion.

Loans

Secure a loan for global expansion

Get financing for international customers

Access funding for capital-intensive projects

Find out how direct lending helped this snack brand go global.

Learn how a Canadian tech firm turns sustainability into global opportunity.

Investments

Get equity capital for strategic growth

Explore how GoBolt built a greener logistics network across borders.

By industry

Featured

See how Canadian cleantech firms are advancing global sustainability goals.

Build relationships with global buyers to help grow your international business.

Resources

Popular topics

Explore strategies to enter new markets

Understand trade tariffs and how to manage their impact

Learn ways to protect your business from uncertainty

Build stronger supply chains for reliable operation

Access tools and insights for agri-food exporters

Find market intelligence for mining and metals exporters

Get insights to drive sustainable innovation

Explore resources for infrastructure growth

Export stage

Discover practical tools for first-time exporters

Unlock strategies to manage risk and boost growth

Leverage insights and connections to scale worldwide

Learn how pricing strategies help you enter new markets, manage risk and attract customers.

Get expert insights and the latest economic trends to help guide your export strategy.

Trade intelligence

Track trade trends in Indo-Pacific

Uncover European market opportunities

Access insights on U.S. trade

Browse countries and markets

Get expert analysis on markets and trends

Discover stories shaping global trade

See what’s ahead for the world economy

Monitor shifting global market risks

Read exporters’ perspectives on global trade

Knowledge centre

Get answers to your export questions

Research foreign companies before doing business

Find trusted freight forwarders

Gain export skills with online courses

Discover resources for smarter exporting

Get insights and practical advice from leading experts

Listen to global trade stories

Learn how exporters are thriving worldwide

Explore export challenges and EDC solutions

About

Discover our story

See how we help exporters

Explore the companies we serve

Learn about our commitment to ESG

Understand our governance framework

See the results of our commitments

MyEDC account

Manage your finance and insurance services. Get access to export tools and expert insights.

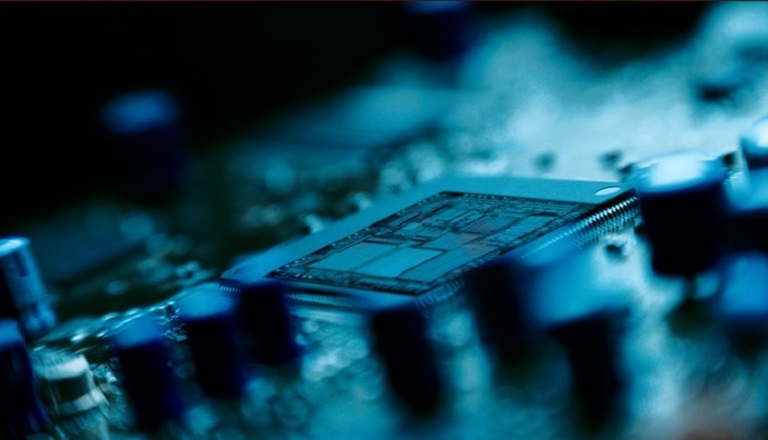

Based in Ottawa’s technology corridor, GaN Systems is an Export Development Canada 2020 Cleantech One-to-Watch.

In the 1990s, the creation of gallium nitride (GaN) was a major breakthrough for the semiconductor industry. It is now moving beyond the limitations of legacy silicon systems and revolutionizing energy efficiency and design of power systems in industries including electric vehicles, consumer electronics, data centres, and renewable energy.

GaN Systems, based in Kanata, ON, is driving this industry-changing advancement with its new generation of power transistors. The company is enabling some of the largest electronics customers in the world to decrease the size and cost of their power systems while increasing their speed and efficiency at the same time.

Like a microprocessor chip is the most important piece in a computer’s brain, power transistors are the key components of any power system–whether it’s a power adaptor for a cell phone or the on-board charger (OBC) for an electric vehicle. Their basic function is to turn on and off rapidly to obtain the desired voltage and current profile to power a device.

GaN transistors have very low resistance and can be turned on and off incredibly fast: as much as 1,000 times faster than silicon transistors. Some of our customers’ power systems will turn the GaN transistors on and off as much as a million times per second. The ability to increase this frequency means that the components in the power system can be reduced in size. For example, with GaN transistors, a four-fold increase in frequency can create a four-fold reduction in size, cut power loss (waste) by four times, and make the components four times smaller and four times lighter. That means, customers can create notably more energy efficient designs but also reduce the building materials costs for power systems by roughly 10%.

The need for more efficient power conversion is an important element of moving the world to a more energy efficient and carbon-free economy. That’s why we target our products to areas with the potential for significant impact, including:

One of the challenges for us across markets is that the power systems market is usually very conservative in adopting and using new technology and for good reason. In a typical low-cost consumer electronics device like a charger, failure might mean a bad user experience or the need to replace the component. But when a power system component fails in an electric vehicle, the consequences are significant.

Big companies usually like to buy from other big companies. Even thoughwe’re a mid-sized, but rapidly growing company, we design and build the best performing parts that has allowed us to partner with recognized leaders in the industry and supply products to well-known global brands. We build reference design circuit boards using our transistors in collaboration with partner’s Integrated Circuit semiconductors, so potential customers can see how they work together. This has also helped big companies recognize GaN Systems as an important player.

My experience has taught me that there are two kinds of companies when it comes to adopting new products:

Here at Gan Systems, we’re starting to see the latter group now adapting GaN, for example, in the phone and computer charger market.

The electronics industry is global and it’s important for us to work closely with our worldwide customers in the design of their products at the earliest stages. Over the past six years, we’ve spent a lot of time showing people how GaN transistors work, how to get the most benefit from them and drive system costs down. To do all of this, we have applications engineering labs in four countries throughout North America and Asia, where we build evaluation circuit boards for our customers.

We’re a global company with a workforce spread across several continents. It was fortunate that we were already a big user of collaboration tools–which helped us transition to work from home during COVID-19.

But not all of our work can be done remotely. We still need staff in our labs to continue doing the evaluation work and people in the factory to continue making our products. Fortunately, most of our products are made in Taiwan where the response to COVID-19 has been among the best in the world, which has helped sustain productivity.

GaN Systems is also fortunate that semiconductor manufacturers have been declared essential businesses throughout most of the world. In fact, demand for our products from customers in the computer and data centre industries has never been higher, largely fuelled by the sudden worldwide shift to remote working arrangements and the devices and infrastructures needed to support them. Energy is the top cost for data centres, making efficient power conversion a considerable cost-savings benefit, while reducing their energy requirements at the same time.

GaN Systems was founded in 2009 after we developed our first device in the National Research Council Canada lab in Ottawa with help from Sustainable Development Technology Canada (SDTC). In 2014, again with help from SDTC, we launched our products into the marketplace and we’re now in high-volume, high-growth mode. At this stage, access to working capital can be a growth accelerating or throttling factor. There’s a long lag between when we buy our inputs and when we get paid for our products and that can add up to millions of dollars. Export Development Canada’s recent investment in GaN Systems, as well as security they provide to our bank through the Export Guarantee Program, has provided us with access to working capital, so we can continue fulfilling larger orders and continue on our growth trajectory.

For more on GaN Systems, watch the video below.

Learn about the opportunities that green recovery plans present for Canadian cleantech exporters.

Part 1 of 5 in series

Part 2 of 5 in series

Smarter intersections: Traffic management gets pulled into right lanePart 3 of 5 in series

Power up: Smart grid technology

Canada’s new Indo-Pacific Agriculture and Agri-Food Office serves up more opportunities for exporters.

Discover how an export diversification strategy can reduce risk and open new global opportunities.

Learn how U.S. steel and aluminum tariffs impact supply chains and how to mitigate their effects.

Discover how market diversification can enhance your export strategy and provide new ways for your business to grow in today’s uncertain trade climate.

Certificates of origin (COs) are legal documents that declare the origin of a product. When you export goods to an overseas customer, you must include a CO with your shipment.