Labour shortage? Put tech to work for you

Author details

Jane Daly

Senior contributing international trade writer,

Some 63% of Canadian companies say the labour shortage is hurting them, a situation that’s estimated to cost Canada $39 billion in lost gross domestic product (GDP) by 2030. Here’s how you can use technology to deal with your capacity crisis, with help from Export Development Canada (EDC).

In this article:

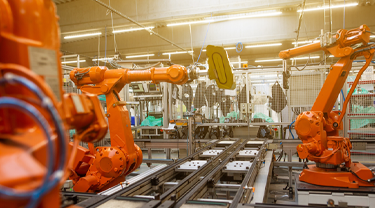

Imagine hiring a new employee who could make quick work of increasing the quality of your products, and the productivity and efficiency of your manufacturing plant, all without taking a break. Companies across Canada and around the world are already installing automated and robotic “colleagues” to keep their operations thriving – despite the labour shortage.

The hospitality industry, one of the hardest hit by the lack of skilled workers, also uses robots to take orders and serve food. And there are many other technologies helping businesses of every size overcome the labour crunch.

Manufacturing, which is faced with a looming wave of retirements, is putting automated machinery, equipped with intelligent software enabled by high-speed, low-latency (fixed and mobile) connectivity, to work for them.

Geofencing (software that identifies virtual geographical boundaries and tracks and measures the efficiencies of employees) and drones are taking away the tedious paperwork, clock-punching, and site progress inspections for construction companies, as well as automating operational processes to optimize cash flow.

And that’s not all.

Implementing advanced technology in your business can actually help you attract and retain more top talent of the human variety, especially from the up-and-coming Generation Z (born between 1996 and mid-2000) that want to work for innovative companies.

Using advanced technology for the mundane tasks also frees up staff to do more meaningful work that technology and robots can’t do, like innovation, leveraging emotional intelligence, people management and critical thinking.

5 reasons tech attracts talent

1. A company culture of innovation: Millennial and Gen Z employees, in particular, value innovation and want to work with cutting-edge technology.

2. The ability work remotely: Employees of all generations value the flexibility, cost savings, and work/life balance of remote work.

3. Enhanced collaboration: With the latest technology, employees can collaborate more effectively, whether they’re in the same office or half a world away.

4. Professional development: Learning to use the latest technology and automation provides valuable skills employees can use to advance and enhance their employable skills.

5. More sustainable workplace: Automation technologies can increase efficiency, while smart heating, cooling, and lighting systems can optimize energy usage, all leading to more sustainable footprints that workers of all ages increasingly value.

“A number of Canadian businesses are global leaders in producing advanced technologies,” says Vikas Arora, principal and technology lead, Mid-Market Growth Business, at Export Development Canada (EDC). “Businesses around the world are implementing Canadian technologies that are revolutionizing the way we work in manufacturing, logistics, mining, farming, industrial, and every sector.”

But unlike their global peers, Canadian business owners are failing to embrace the range of game-changing technologies that can help them increase agility, productivity and innovation.

“Canada has fallen way behind the United States and Europe, where technology is viewed as an investment, a winning strategy to deal with labour shortages,” Arora says. “Canadian companies tend to see technology as an expense and a risk—something that will force a change in operations that they’re not even sure they need.”

Even if a company does manage to find new employees, Arora says, failing to build their tech-intensity in this Fourth Industrial Revolution means they’ll still be left behind.

“We believe digital technologies will play a critical role in enabling operational efficiencies, speed, agility and innovation, and drive global competitiveness,” he says, adding that preparing for the future is key.

“Businesses should rapidly use this opportunity to build their operational excellence with fast adoption of technology, integration of proprietary expertise, and access to real-time data.”

And he’s optimistic Canadian companies will apply learnings gained over the last several years for future growth.

“During the pandemic, Canadian companies rose to the occasion to implement innovations such as remote working technologies and online shopping platforms. I believe they’re braver than they think.”

Despite a small uptick of 0.1% in Canadian employment levels in February 2023, labour-force participation rates remain stagnant, and the unemployment-to-job-vacancy ratio is at a historical record low across all provinces.

And companies are hurting. According to Statistics Canada, the labour shortage is affecting 37% of companies, with construction (49.5%) and manufacturing (47.4%) faring the worst. The Canadian Federation of Independent Business (CFIB) also found that 56% of surveyed businesses say labour shortages have severely impacted their operations, and a survey by the Canadian Manufacturers and Exporters (CME) found 84% of Canadian manufacturers are concerned about the impact of the labour shortage on their ability to compete globally.

“Canadian business owners are having to turn down orders due to lack of capacity, and that means they’re growing slowly or not at all,” says Arora. “Not to mention, the harm it’s doing to customer satisfaction and loyalty.”

With the dire need to overcome the labour shortage, Arora advises companies to take action. “Some businesses are investing in an entire factory retrofit, but for smaller companies, even a modest investment in technology can help deal with labour shortages, as well as increase productivity, efficiency, and safety, while reducing errors and costs.” Options include:

- Robotics systems can be used for assembly, material handling, and inspection.

- Collaborative robots (cobots) work alongside humans, assisting with assembly, material handling or hazardous tasks.

- Automated mobile robots (AMRs) transport items within a facility.

- Geofencing pinpoints the time a work crew arrives or leaves a site, automatically generating timesheets, invoices and payment.

- Drones can speed up data collection to track progress, perform inspections (including hazardous tasks), track asset movements, and enable site monitoring.

- Software and artificial intelligence (AI) can also optimize manufacturing processes such as scheduling, inventory management, or quality control.

“Once you’ve overcome the fear of technology and are ready to reap the advantages, you can use EDC to get started or expand the technology you already have,” Arora says. EDC can help you:

- Feel more confident about making informed decisions: EDC has a wealth of research and market expertise, as well as experience working with other companies to help them with automation and technology transitions.

- Get connected: EDC takes tech seriously, and that involves making key connections within the advanced technology sector. We can help connect you with the people and resources you need to get started.

- Get the financing you need to make the transition: EDC’s cost-effective guaranteed loans and lines of credit can encourage your financial institution to increase your available financing, so you can purchase technology and equipment to expand your capacity. Solutions include:

- EDC Export Guarantee Program (EGP) provides guarantees for up to US$10 million to your financial institution, so they can extend your line of credit, provide term loans or margin international assets or inventory, reducing the risks for your lender.

- EDC Credit Insurance protects your company against the risk of non-payment, which can help free up your cash flow to invest in technologies.

- EDC financing solutions helps high-growth companies with strong management teams and track records grow and expand, including their investments in technology and automation.